Professional graphite material supplier, graphite for EV, grease, furnace and any other industries.

(What is expanded graphite?)

What is expanded graphite?

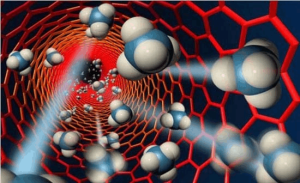

Graphite crystals have a hexagonal mesh planar layer structure consisting of carbon elements. The carbon atoms in the layer planes are bonded with strong covalent bonds, while the layers are bonded to each other by van der Waals forces with very weak bonds and large interlayer distances. Therefore, under the right conditions, a variety of chemicals such as acids, alkali metals and salts can be inserted between the graphite layers and combine with the carbon atoms to form a new chemical phase – Graphite Intercalation on Compounds (GIC). When heated to the right temperature, this intercalation compound decomposes instantly and rapidly, producing a large amount of gas that expands the graphite into a new worm-like substance along its axis, known as expanded graphite. This unexpanded graphite interlayer compound is expandable graphite.

What is the characteristics of expanded graphite?

Excellent resistance to pressure, flexibility, plasticity and self-lubrication;

Excellent resistance to high and low temperatures, corrosion and radiation;

Extreme resistance to vibration;

Extreme electrical conductivity;

Extremely strong anti-aging and anti-distortion properties;

Resistant to melting and penetration of various metals;

Non-toxic and free of carcinogens, no harm to the environment;

The expansion characteristics of expandable graphite flakes are different from other expansion agents. When heated to a certain temperature, the expandable graphite starts to expand due to the decomposition of the compound absorbed in the interlayer dot matrix, which is called the starting expansion temperature, and expands completely at 1000°C to reach its maximum volume. The expansion volume can reach more than 200 times the initial volume. The expanded graphite is called expanded graphite or graphite worm, which changes from the original scale shape to a very low density worm shape, forming a very good insulation layer. Expanded graphite is both a source of carbon in the expansion system and an adiabatic layer that provides effective thermal insulation and has a low heat release rate, low mass loss and produces less smoke in a fire.

What is the application of expanded graphite?

Sealing material The raw material of high carbon graphite is mixed with concentrated sulphuric acid and nitric acid, acid-treated, heat-treated and then pressed into shape to produce a new type of high-performance sealing material, which is a kind of in situ-grown nano-material. Compared with traditional sealing materials such as asbestos rubber, it has good compressibility, resilience, self-bonding, low density and other excellent properties, and can be used under high temperature, high corrosion and other harsh working conditions for a long time. Graphite sheets and sealing elements made from it are widely used in aerospace, machinery, electronics, nuclear energy, petrochemical, electric power, shipping, smelting and other industries. Because it has a light weight, electrical conductivity, thermal conductivity, high temperature, acid and alkali corrosion resistance, good resilience, lubricity, plasticity and chemical stability and other excellent characteristics, known as the world's "king of the seal".

Environmental protection field High-temperature expansion of expandable graphite, with a rich pore structure, and thus has excellent adsorption properties, so in environmental protection and biomedical science has a wide range of uses. The pore structure of expandable graphite has two kinds of open pores and closed pores, the pore volume accounts for about 98%, and the pore size distribution is mainly in the range of 1~10.3 nm. As it is mainly large and medium pores, so it is different from activated carbon and other microporous materials in terms of adsorption characteristics. It is suitable for liquid-phase adsorption, but not for gas-phase adsorption. In the liquid phase adsorption it is lipophilic and hydrophobic. 1 g of expandable graphite can adsorb more than 80 g of heavy oil, so it is a very promising environmental protection material to remove oil pollution on the water surface. In the chemical enterprise wastewater treatment, often using microbial (bacteria) treatment, expandable graphite is a good microbial carrier, especially for oil and grease organic macromolecule pollution of water treatment, due to good chemical stability, and can be regenerated and reused, so there is a good prospect of application.

Medical As expandable graphite has the adsorption characteristics of organic and biological macromolecules, in biomedical materials have a wide range of application prospects.

High-energy battery materials Expandable graphite as a battery material, is the use of expandable graphite interlayer reaction of free energy changes into electricity. Usually swellable graphite as the cathode, lithium as the anode, or swellable graphite composite silver oxide as the cathode, zinc as the anode. Graphite fluoride, graphite acid and AuCl3 and TiF4 and other metal halide expandable graphite has been applied to the battery.

Fireproof and flame-retardant

Fire seals Due to the expandability of expandable graphite and its high temperature resistance, expandable graphite has become an excellent sealing material and is widely used in fire seals. There are two main forms: the first is expandable graphite materials and rubber materials, inorganic flame retardants, accelerators, vulcanizing agents, reinforcing agents, fillers and other mixing, vulcanization, molding, made of various specifications of the expansion of the seal, mainly for fire doors, fire windows and other occasions. This kind of expansion sealing strip can play the role of blocking the flow of smoke from beginning to end at room temperature and in fire. The other is a glass fibre tape as a carrier, expandable graphite with some kind of adhesive bonded to the carrier, this adhesive at high temperatures when the formation of the shear resistance provided by the carbide can effectively prevent the graphite sliding. It is mainly used in fire doors, but it does not effectively block the flow of cold smoke at room temperature or at low temperatures, so it must be used in conjunction with room temperature sealants.

What are the advantages of expanded graphite?

Expandable graphite is a good flame retardant for plastic materials, it is non-toxic and non-polluting, and can be used alone or mixed with other flame retardants to achieve the desired flame retardant effect. The amount of expandable graphite used to achieve the same flame retardant effect is much less than that of ordinary flame retardants. The principle of its action is: at high temperatures, expandable graphite expands rapidly, suffocating the flame, while the graphite expanded material generated by it covers the surface of the substrate, isolating the heat radiation and oxygen contact; the acid inside the sandwich layer is released during expansion, which also promotes the carbonisation of the substrate, thus achieving good results through a variety of flame retardant methods.

High quality expanded graphite supplier

Luoyang Moon & Star New Energy Technology Co., LTD, founded on October 17, 2008, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of lithium ion battery anode materials, we are high quality graphite supplier.

Our Company has a diversified product structure with natural graphite, artificial graphite, composite graphite, intermediate phase and other negative materials (silicon carbon materials, etc.). The products are widely used in high-end lithium ion digital, power and energy storage batteries. If you are looking for graphite powder, please contact us. Or click on the needed products and send us an inquiry:sales@graphite-corp.com

(What is expanded graphite?)