Professional graphite material supplier, graphite for EV, grease, furnace and any other industries.

(What Is Graphite Lubricant)

Graphite lubricants: A Practical Guide

(What Is Graphite Lubricant)

Graphite lubricants are a type of lubricant that is specifically formulated to be compatible with graphite, which is the primary component of industrial tools such as hand tools, chucks, and drills. With its unique properties and effectiveness, graphene lubricants have become an essential tool in many industries. In this blog post, we will explore some fascinating aspects about graphene lubricants.

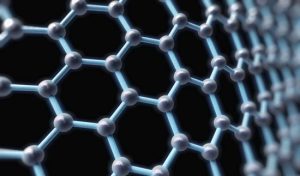

1. What is Graphite?

Graphite is a blend of iron and carbon dioxide formed during the fusion process of volcanic ash. It is characterized by its soft, pliable nature and is often used as a means of improving the performance of various types of tools.

2. How is Graphite Relined?

Graphite lubricants are typically made by blending the components of graphite with a mixture of oil, lubro Pigment, or other additives. These mixtures are then treated to form a paste-like consistency, making it easier for the materials to adhere together.

3. Advantages of Graphite?

One of the key advantages of using graphene lubricants is their durability. Graphite is lightweight, non-toxic, and has low friction, making it ideal for use in harsh working conditions.

Another advantage of graphene lubricants is their low cost. Graphite lubricants can be affordable, especially when compared to other lubricants, due to their lower cost of production.

4. Different Types of Graphite Lubricants

There are several different types of graphene lubricants available, each with its own set of characteristics and applications. Some common types include:

– Smoother than.Base-Low wax lubrifier: This type of lubricant provides more control over how the oil flows through the lubricant and reduces friction.

– Medium-Smoother than Base-Low wax lubrifier: This type of lubricant provides slightly more control over how the oil flows through the lubricant and reduces friction.

– Upper-Band/Lower-Band lubricant: This type of lubricant provides more control over how the oil flows through the lubricant and reduces friction.

5. Use in Industrial Applications

In addition to its practical uses, graphene lubricants also have applications in a variety of industrial settings. For example, they can be used in mechanical surgeries to provide lubrication for surgical instruments and equipment. They can also be used in precision machinery to ensure accurate movement and performance.

6. Conclusion

(What Is Graphite Lubricant)

Graphite lubricants have become increasingly popular in recent years due to their unique properties and benefits. Whether you’re looking to improve the performance of your tools or make modifications to your operations, graphene lubricants offer a reliable and cost-effective solution. With their low cost and ability to reduce friction, graphene lubricants are a valuable asset in any industry. hot tags: graphite,graphite powder,nano graphite

(What Is Graphite Lubricant)