Professional graphite material supplier, graphite for EV, grease, furnace and any other industries.

Conductive Carbon Black

High Surface Area Activated Carbon Powder Conductive Carbon Black low N330 N220 High Purity Electrical Conductive

Factory whole black active carbon face mask conductive nano carbon black powder factory

CNTs-PC conductive masterbatch high concentration and high conductivity carbon nanotube masterbatch

Direct Supply Of Fuel Electrode Carbon Paper Conductive Carbon Cloth Conductive Carbon Fiber Multi-Axial Fabric Cloth

100% Carbon Fiber Super Conductive 0.3-0.32mm Carbon Cloth Gas Diffusion Layer and Electrode for Fuel Cell

Super Conductive Carbon Black Powder For Lithium Battery Materials 7KG/bag

HUMANCHEM HTC-08 Water-based graphene carbon conductive coating for Cu cathode substrate

JoinedFortune high carbon rp graphite electrode graphite electrode with nipple pour electrolyse

Carbon Black Hybrid Carbon Black

Water-based conductive carbon black slurry Dispersant RD-9281 has excellent wetting and viscosity reduction properties

Carbon Black N762

Conductive carbon black SP Low resistivity good thermal conductivity powdery carbon black

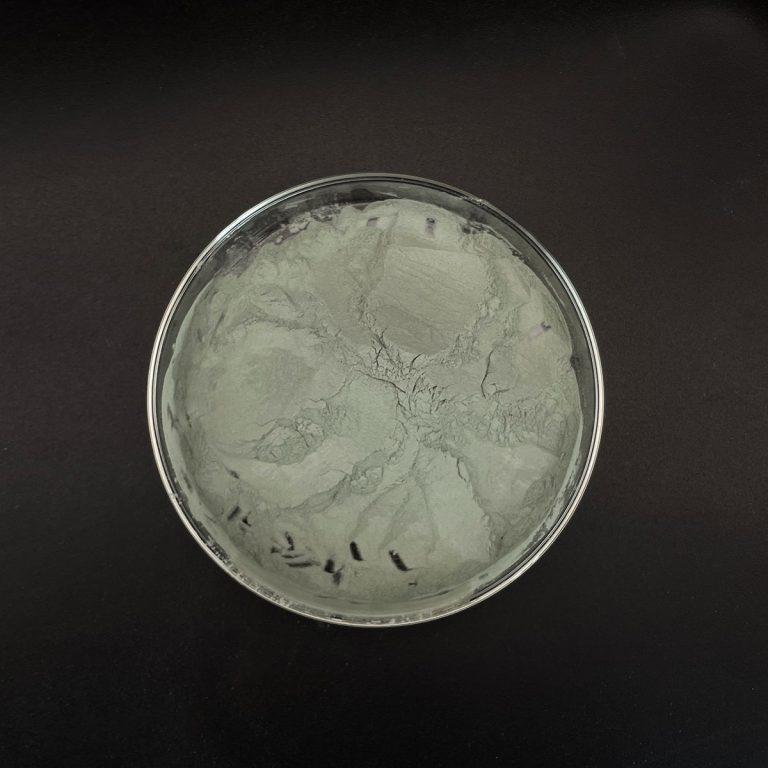

Introduction of High Purity Graphite

High purity graphite, also known as high-purity carbon or synthetic graphite, is a form of graphite that has been processed to achieve very low levels of impurities. It is typically defined as having a carbon content of 99.9% or higher, with minimal amounts of other elements such as sulfur, ash, and metallic elements. This type of graphite is produced through a series of purification processes, including chemical treatment, heat treatment, and mechanical processing.

Features of High Purity Graphite

- High Thermal Conductivity: High purity graphite can conduct heat very efficiently, making it useful in applications where thermal management is critical.

- Low Electrical Resistance: It possesses excellent electrical conductivity, which is beneficial for use in electrodes and other electrical components.

- Chemical Inertness: The material is highly resistant to most chemicals, allowing it to be used in corrosive environments.

- Self-Lubricating Properties: High purity graphite can act as a lubricant under certain conditions, reducing friction without the need for additional lubricants.

- High Temperature Stability: It maintains its structural integrity at extremely high temperatures, making it suitable for high-temperature applications.

- Machinability: It can be easily machined into various shapes and sizes, facilitating its use in a wide range of products.

Applications of High Purity Graphite

- Electronics Industry: Used in the production of semiconductors, as well as in the manufacturing of silicon wafers and other electronic components.

- Metallurgy: Employed as an electrode material in electric arc furnaces for steelmaking and other metal refining processes.

- Nuclear Industry: Utilized in nuclear reactors due to its neutron moderation properties and ability to withstand high radiation levels.

- Aerospace: Used in rocket nozzles, re-entry shields, and other high-temperature aerospace applications.

- Laboratory Equipment: Found in crucibles, boats, and other labware that must resist high temperatures and aggressive chemicals.

- Energy Storage: Applied in batteries and fuel cells, particularly in lithium-ion battery anodes.

- Mechanical Engineering: As bearings, seals, and gaskets in pumps and valves where conventional materials would fail.

About us

Graphite-corp was founded in 2008 and is a high-tech enterprise specializing in the researching and developing, producting, and sales of graphite materials. Our products include but not limited to Flake Graphite, Expandable Graphite, Spherical Graphite, Graphite Powder, Medium Carbon Flake, High Carbon Flake and High Purity Graphite, etc. If you are interested, please feel free to contact us!(sales@graphite-corp.com)

Payment Term

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment Term

By sea, by air, by express, and as customers request.

Storage conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

FAQs

Q: What is the difference between natural and synthetic high purity graphite?

A: Natural graphite is mined from the earth and then purified, while synthetic graphite is made by processing petroleum coke or coal tar pitch at very high temperatures. Synthetic graphite tends to have a more uniform structure and higher purity levels.

Q: How is high purity graphite manufactured?

A: The process usually involves the selection of raw materials, followed by calcination, graphitization, and purification steps. Advanced techniques like acid leaching and high-temperature treatments may also be employed to remove impurities.

Q: Can high purity graphite be recycled?

A: Yes, to some extent. After use, graphite can be reclaimed and reprocessed, though the cost and complexity of this process can vary.

Q: Is high purity graphite environmentally friendly?

A: While the production of high purity graphite can have environmental impacts, especially if not managed properly, the material itself is inert and does not pose significant environmental risks when used correctly.

Q: What safety precautions should be taken when handling high purity graphite?

A: Although generally safe, it's important to avoid inhaling dust, as it can irritate the respiratory system. Proper protective equipment, such as gloves and masks, should be worn during handling.