Professional graphite material supplier, graphite for EV, grease, furnace and any other industries.

Graphite Powder

HUAHONG Timely Delivery Powder Metallurgy Sintering 2400C Graphite Vacuum High Temperature Metal Sintering Furnace

femfresh body fresheners range powder 200g talc fr talc, mica, magnesium stearate, silica, polyethyle 80/20 talc/graphite

Carbon UHP High Power RP 100 200 300 400 500 600 rod Hige temperature resistance small Graphite electrode

high temperature induction type vacuum graphite powder graphitization industrial oven

Carbon material graphite purification lithium battery anode material automatic sintering vacuum atmosphere sintering furnace

With Factory Coal Briquette Production Line For Fluorite Powder, Chemical Salt, Graphite

High Purity UHP HP RP SHP Grade Graphite Electrode Rod With Best

0-1 1-5 3-8 8-26mm GPC Graphite Semi Graphitized Pet Coke Steelmaking Carbon Additive Foundry Metallurgical Met Calcined

Graphite Boat Spray YSZ powder BP-160 Plasma Spray Equipment with Spray Gun Powder coating machine HVOF ARC Equipment

Heat Insulation Boron Nitride Tube for Graphite Electrode

High Performance Factory s Stainless Steel 600mm~1500mm Graphite Powder Ultrasonic Vibrating Sieve Machine

LNPE Graphite Powder Spheroidization Mill/Shaping Mill

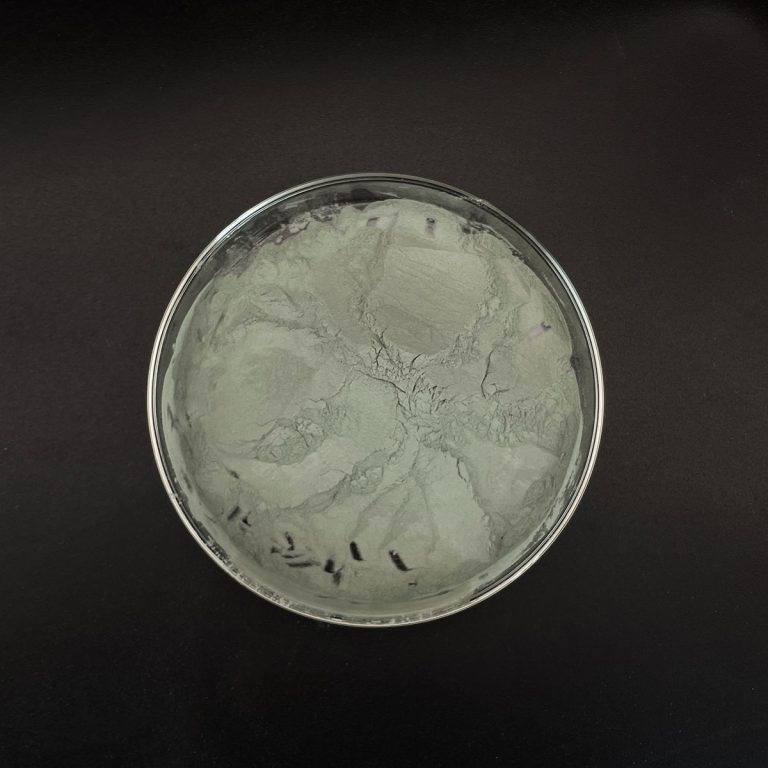

Introduction of Graphite Powder

Graphite powder is soft, black and gray; has a greasy feel. Under the condition of oxygen isolation, its melting point is above 3000 ℃. At normal temperature, the chemical properties of graphite powder are relatively stable, insoluble in water, dilute acid, dilute alkali and organic solvents.

Features of Graphite Powder

- High Carbon Content: Graphite powder is characterized by a high carbon content, typically above 90%, with some grades reaching up to 99.9%.

- Lubricating Properties: Due to its layered structure, graphite powder can act as an excellent dry lubricant, reducing friction and wear in machinery without the need for liquid lubricants.

- Thermal Conductivity: It has good thermal conductivity, making it suitable for applications that require heat dissipation, such as in electronics and furnace linings.

- Electrical Conductivity: Graphite powder is a good conductor of electricity, which makes it useful in batteries, electrodes, and other electrical components.

- Chemical Inertness: It is resistant to most chemicals and can be used in corrosive environments.

- Refractory Characteristics: Graphite powder can withstand high temperatures without melting, making it ideal for use in refractory materials and high-temperature applications.

- Moldability and Flexibility: It can be easily molded and mixed with other materials to form composites or pressed into various shapes.

- Non-toxic and Environmentally Friendly: Generally considered non-toxic and environmentally friendly, especially when compared to some synthetic alternatives.

Applications of Graphite Powder

Graphite has good chemical stability. Specially processed graphite has the characteristics of corrosion resistance, good thermal conductivity, and low permeability. It is widely used in the manufacture of heat exchangers, reaction tanks, condensers, combustion towers, absorption towers, coolers, heaters, filters , Pump equipment. It is widely used in petrochemical industry, hydrometallurgy, acid-base production, synthetic fiber, papermaking and other industrial sectors, which can save a lot of metal materials. Graphite is also a polish and rust inhibitor for glass and paper in the light industry. It is an indispensable raw material for the manufacture of pencils, inks, black paints, inks and artificial diamonds and diamonds. It is a good energy-saving and environmentally friendly material and can be used as a car battery. With the development of modern science and technology and industry, the application field of graphite is still expanding. It has become an important raw material for new composite materials in the high-tech field, and plays an important role in the national economy.

About Us

Graphite-corp was founded in 2008 and is a high-tech enterprise specializing in the researching and developing, producting, and sales of graphite materials. Our products include but not limited to Flake Graphite, Expandable Graphite, Spherical Graphite, Graphite Powder, Medium Carbon Flake, High Carbon Flake and High Purity Graphite, etc. If you are interested, please feel free to contact us!(sales@graphite-corp.com)

Payment Term

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment Term

By sea, by air, by express, and as customers request.

Storage conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

FAQs

Q: What are the main types of graphite powder?

A: The main types include natural flake graphite, amorphous (microcrystalline) graphite, and synthetic graphite. Each type has different properties and is suited for specific applications.

Q: How is graphite powder produced?

A: Natural graphite powder is obtained from mining and then processed through milling and purification. Synthetic graphite is produced by heating petroleum coke or coal tar pitch in an electric furnace.

Q: Can graphite powder be used in food-grade applications?

A: Yes, certain grades of graphite powder that meet specific purity and safety standards can be used in food-grade applications, such as release agents in baking or as a component in some food processing equipment.

Q: Is graphite powder safe to handle?

A: While generally safe, it's important to handle graphite powder with care. Inhalation of fine particles should be avoided, and protective measures like wearing a dust mask and working in a well-ventilated area are recommended.

Q: What is the difference between graphite powder and graphene?

A: Graphene is a single layer of graphite atoms arranged in a two-dimensional honeycomb lattice. Graphite powder consists of many layers of graphene stacked together. Graphene has unique properties, such as exceptional strength and conductivity, but is more challenging to produce and work with than graphite powder.

Q: Can graphite powder be recycled?

A: Yes, graphite powder can be recovered and reused from various applications, including spent batteries and industrial waste, through recycling processes.

Q: What are the environmental impacts of using graphite powder?

A: The environmental impact of graphite powder is relatively low, especially if sourced from natural deposits and handled properly. However, the mining and processing of natural graphite can have local environmental impacts, and synthetic graphite production requires significant energy input. Recycling and proper disposal practices help mitigate these impacts.

Q: How does the particle size of graphite powder affect its performance?

A: The particle size can significantly affect the performance of graphite powder. Finer particles generally provide better lubrication and dispersion in composites, while larger particles may be preferred for their mechanical stability in certain applications.